3D Printers: Most Anticipated Trends for 2025

- 26 Mar, 2025

- Home

- 0 Comments

3D Printers: Most Anticipated Trends for 2025

3D printers are rapidly revolutionizing the way we manufacture objects, prototypes, and even complex structures. With 2025 approaching, experts predict significant changes in the additive manufacturing industry.

Artificial intelligence, large-scale industrial adoption, sustainability, and new materials will be at the forefront of this evolution. Let's explore the most anticipated innovations and how they will shape our future.

Artificial Intelligence Optimizes 3D Printers

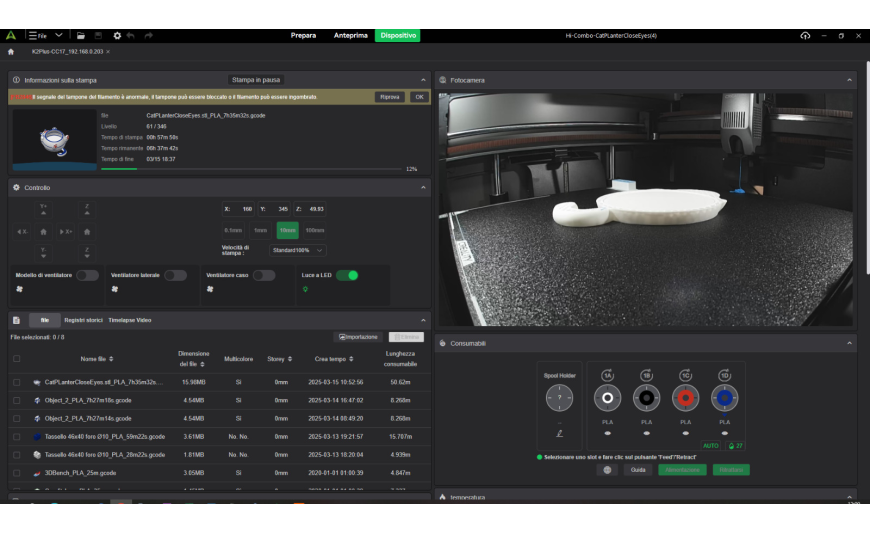

The integration of artificial intelligence (AI) in the 3D printing industry is growing exponentially. Smart printers will be able to analyze every stage of the process in real time, reducing errors and optimizing print quality.

AI will be used to:

Improve precision of models by automatically adjusting temperature and printing speed parameters.

Predict failures and malfunctions through predictive maintenance, reducing machine downtime.

Optimize material usage, minimizing waste and lowering production costs.

These innovations will make 3D printers more reliable and easier to use, paving the way for new industrial and commercial applications.

New Materials for 3D Printers

Innovation in printing materials is one of the key factors driving the industry's expansion. In 2025, we will see an increase in the use of advanced materials such as:

Conductive polymers, enabling the printing of electronic circuits directly within objects.

Biodegradable bioplastics, making 3D printing more sustainable and environmentally friendly.

High-strength lightweight metals, such as titanium and aluminum alloys for the aerospace and automotive industries.

Biocompatible materials, ideal for producing customized medical implants and prosthetics.

These innovative materials will expand the applications of 3D printers, revolutionizing fields such as medicine, electronics, and engineering.

3D Printers and Sustainability

The focus on sustainability is an unstoppable trend in the 3D printing industry. Among the key innovations of 2025, we find:

Waste reduction, thanks to the use of recycled and biodegradable materials.

Decentralized production, which reduces carbon emissions related to transportation by producing objects directly on-site.

Reuse of waste materials, transforming them into new printing filaments.

These developments will make 3D printers an increasingly eco-friendly and cost-effective solution, perfect for a circular economy.

3D Printing on an Industrial Scale

2025 will mark a turning point in the large-scale adoption of 3D printing. Industries such as automotive, aerospace, and defense will increasingly invest in large-format industrial printers.

The main innovations will focus on:

High-speed printers, capable of producing components in record time.

Hybrid technologies, combining 3D printing with traditional manufacturing methods.

Large-scale customization, making production more flexible and adaptable to customer needs.

Industrial-scale adoption will transform 3D printing from a simple prototyping tool into a highly efficient mass production method.

Personalization and Customization

One of the key strengths of 3D printing is the ability to customize each product according to the user's needs. This trend will continue to grow in 2025, with applications in sectors such as:

Healthcare, with custom prosthetics and dental implants.

Fashion and design, to create unique clothing and accessories.

Automotive, with customized components for each vehicle.

Thanks to advancements in 3D modeling software and materials, customization will become increasingly accessible to the general public.

Multi-Material and Multi-Color 3D Printing

Another rapidly growing trend is 3D printing with multiple materials and colors in a single session. This will enable the creation of more complex and functional products with different mechanical properties within the same object.

The most anticipated innovations include:

Material jetting 3D printers, capable of combining polymers, metals, and ceramics.

Advanced 3D inks, allowing the creation of objects with vibrant colors and precise details.

4D printing technologies, enabling the production of objects that can change shape over time.

These technologies will pave the way for new possibilities in design, industrial production, and even robotics.

Conclusion

3D printers are revolutionizing the manufacturing industry, and in 2025 we will witness extraordinary advancements. From AI integration to extreme customization and sustainability, the future of 3D printing looks more promising than ever. Those who seize these opportunities will gain significant advantages in terms of efficiency, innovation, and competitiveness.

You must be logged in to post comments